Introduction: The chemical name of Empagliflozin is (2S,3R,4R,5S,6R)-2-[4-chloro-3-[[4-[(3S)-oxolan-3-yl]oxyphenyl]methyl]phenyl]-6-(hydroxymethyl)oxane-3,4,5-triol (Fig. 1).

Empagliflozin exhibits antidiabetic activity and is primarily prescribed for the management of type 2 diabetes mellitus. Its mechanism of action involves the inhibition of the sodium-glucose cotransporter-2 (SGLT-2). By blocking this transporter, the drug lowers blood glucose levels through reduced renal glucose reabsorption and enhanced urinary glucose excretion [1–2].

Metformin, chemically known as 3-(diaminomethylidene)-1,1-dimethylguanidine (Fig. 1), reduces glucose absorption from the gastrointestinal tract and suppresses hepatic gluconeogenesis, while simultaneously enhancing glucose uptake by muscle and adipose tissue. These combined effects contribute to lowering blood glucose levels, making it an effective agent in the treatment of diabetes [3–4].

Fig. 1. Chemical structure of Empagliflozin (a); Empagliflozin Impurity D (b), Empagliflozin Sugar Dimer Impurity (c) and Metformin (d)

From the literature survey, it was observed that several HPLC methods have been reported for the estimation of Empagliflozin and Metformin in pharmaceutical dosage forms, either individually or in combination with other drugs. Additionally, an HPLC method is available for impurity estimation in the drug substance, while a UPLC method has been reported for spiked human plasma as well as for Empagliflozin impurities in combination with other drugs in tablet formulations. However, these reported methods primarily focus on impurity estimation and do not address the quantification of Empagliflozin Impurity D and Empagliflozin Sugar Dimer Impurity [5–15].

Such related substances may arise as impurities during the manufacturing process, from degradation due to improper storage, or as metabolites, and they may exhibit active, inactive, or even toxic properties. To the best of our knowledge, no HPLC method has been reported for the estimation of Empagliflozin Impurity D and Empagliflozin Sugar Dimer Impurity in the combined pharmaceutical dosage form containing Empagliflozin and Metformin. The chemical structures of these impurities are presented in Fig. 1. Therefore, the present study was undertaken to develop and validate an HPLC method for their estimation in pharmaceutical dosage forms.

EXPERIMENTAL

Chemicals and Reagents

Empagliflozin, Metformin, Empagliflozin Impurity D, and Empagliflozin Sugar Dimer Impurity were obtained as gift samples from Pharmatrain Laboratories, Hyderabad. HPLC-grade solvents including water, methanol, and acetonitrile were procured from Merck. Potassium dihydrogen phosphate and orthophosphoric acid were purchased from Finar Chemicals Ltd. Synjardy XR tablets containing Empagliflozin (10 mg) and Metformin (1000 mg) were used for the study.

Instrumentation

Chromatographic analysis was performed using a Waters High-Performance Liquid Chromatography (HPLC) system equipped with a PDA detector and an Inertsil ODS column (4.6 × 150 mm, 5 µm). Data acquisition and processing were carried out using Empower Chromatography Data Management System. Additional equipment used included a Lab India UV/Visible spectrophotometer (Model 3000+), Sartorius weighing balance, and Thermo Orion pH meter.

Chromatographic Conditions

Separation of impurities was achieved on an Inertsil ODS (4.6 × 150 mm, 5 µm) column using a mobile phase consisting of phosphate buffer (pH 3.0; prepared by dissolving 6.8 g of potassium dihydrogen phosphate in 1000 mL of water and adjusting the pH with orthophosphoric acid) and methanol in a ratio of 300:700 (v/v). The flow rate was maintained at 1.0 mL/min, and detection was carried out at 220 nm. The injection volume was 30 µL, with samples maintained at ambient temperature. The total run time was 15 minutes. The mobile phase was also used as the diluent.

Preparation of Standard and Sample Solutions

Preparation of Empagliflozin and Metformin Stock Solution:

Accurately weighed 1000 mg of Metformin and 10 mg of Empagliflozin working standard were transferred into a 100 mL clean, dry volumetric flask. About 70 mL of diluent was added, sonicated until completely dissolved, and diluted to volume with diluent, yielding 100 ppm of Empagliflozin and 10,000 ppm of Metformin.

Preparation of Impurity Stock Solution:

Accurately weighed 1.5 mg each of Empagliflozin Impurity D and Empagliflozin Sugar Dimer Impurity were transferred into a 100 mL volumetric flask. Approximately 70 mL of diluent was added, sonicated for 5 minutes to dissolve completely, and diluted to volume with diluent, resulting in 15 ppm of each impurity.

Preparation of Working Standard Solution:

From the above stock solutions, 15.0 mL of Empagliflozin–Metformin solution and 1.0 mL of impurity solution were transferred into a 100 mL volumetric flask and diluted to volume with diluent. The final concentrations obtained were: 15 ppm Empagliflozin, 1500 ppm Metformin, and 0.15 ppm each of Empagliflozin Impurity D and Empagliflozin Sugar Dimer Impurity.

Preparation of Sample Solution:

Ten Synjardy XR tablets (10 mg/1000 mg formulation) were weighed and powdered using a mortar and pestle. Tablet powder equivalent to 1000 mg of Metformin and 10 mg of Empagliflozin was transferred into a 100 mL clean, dry volumetric flask. About 70 mL of diluent was added, sonicated for 30 minutes to ensure complete extraction, and diluted to volume with diluent. The solution was filtered through a 0.45 µm PVDF syringe filter.

From this stock, 1.5 mL was transferred into a 10 mL volumetric flask, diluted to volume with diluent, and mixed thoroughly before use.

RESULT AND DISCUSSION

Development and Optimization of the HPLC Method

Chromatographic Analysis:

The chromatographic separation and quantification were carried out using a Waters High-Performance Liquid Chromatography (HPLC) system equipped with a Photodiode Array (PDA) detector. This system was chosen due to its high sensitivity and reproducibility, making it suitable for simultaneous detection of Metformin, Empagliflozin, and their associated impurities.

Mobile Phase Optimization:

Several trials were conducted to establish the most effective mobile phase composition. Initially, different buffer–organic solvent systems were evaluated, including Methanol: Ammonium Acetate buffer and Methanol: Phosphate buffer, with systematic variation in pH and solvent ratios. These preliminary trials provided useful insights but did not yield satisfactory resolution and peak symmetry. After extensive experimentation, the mobile phase was optimized to a mixture of Potassium dihydrogen phosphate buffer (pH 3.0) and Methanol in the ratio of 300:700 v/v, which provided sharp, well-resolved peaks with excellent reproducibility and minimal baseline noise.

Wavelength Selection:

For the detection wavelength, a UV spectral scan was performed on a 10 µg/mL solution of Metformin and Empagliflozin prepared in the diluent. The solutions were scanned in the 200–400 nm range using the PDA detector. Both analytes exhibited absorption maxima at 220 nm, and therefore this wavelength was selected for the simultaneous quantification of Metformin, Empagliflozin, and impurities. This choice ensured maximum sensitivity while minimizing interference from excipients.

Column Optimization:

The method was further refined through column optimization studies. Several C18 reversed-phase columns, including Hypersil C18, Lichrosorb C18, and Inertsil ODS C18, were evaluated for their performance. Parameters such as peak resolution, tailing factor, theoretical plate number, and reproducibility were carefully examined. Ultimately, the Inertsil ODS column (4.6 × 150 mm, 5 μm) was selected as the most suitable stationary phase. This column demonstrated superior peak symmetry, resolution, and robustness, fulfilling all system suitability criteria consistently across multiple runs.

Method Validation

The optimized HPLC method was validated in compliance with the International Conference on Harmonisation (ICH) guidelines [16]. The validation parameters included specificity, linearity, precision, accuracy, limit of detection (LOD), limit of quantification (LOQ), and robustness.

Specificity:

To confirm specificity, blank solutions, standard solutions, and Empagliflozin impurity-spiked samples were analyzed under the optimized chromatographic conditions. The results confirmed that no interference was observed from the blank or excipients at the retention time corresponding to the analyte peaks. All peaks were well resolved, and the system suitability test results complied with ICH acceptance criteria. The detailed results are summarized in Table 1, and representative chromatograms are presented in Figure 2, clearly demonstrating the selectivity of the developed method.

Table 1. System suitability results

| Name of component | % RSD from six replicates of standard | USP Plate Count | USP Tailing | USP Resolution |

| Metformin | 2.1 | 5276 | 2.50 | NA* |

| Empagliflozin | 3.0 | 4867 | 2.77 | 3.18 |

| Empagliflozin Impurity D | 4.3 | 4687 | 2.42 | 5.53 |

| Empagliflozin Sugar Dimer Impurity | 3.1 | 4577 | 2.28 | 8.45 |

*NA = Not applicable

Fig. 2. Typical chromatogram of blank (a); working standard solution (1st Injection) (b) and Impurity spiked sample solution (c)

Forced Degradation Study

A comprehensive forced degradation (stress testing) study was conducted to evaluate the intrinsic stability profile of Empagliflozin in the presence of its excipients. Such studies are critical for understanding potential degradation pathways, establishing the stability-indicating power of the analytical method, and ensuring the reliability of the assay during routine quality control.

In this investigation, a sample spiked with a known concentration of Empagliflozin impurities was deliberately subjected to a series of stress conditions representing acidic, alkaline, oxidative, photolytic, and thermal environments. The specific conditions applied were as follows:

- Acidic degradation: 3 mL of 0.1 N HCl, maintained at 60 °C for 6 hours.

- Alkaline degradation: 3 mL of 0.1 N NaOH, maintained at 60 °C for 6 hours.

- Oxidative degradation: 1 mL of 3% v/v hydrogen peroxide (H₂O₂), kept at room temperature for 15 minutes.

- Photolytic degradation: direct exposure to natural sunlight for 24 hours.

- Thermal degradation: storage in a hot-air oven at 110 °C for 24 hours.

Following exposure, all stressed samples were analyzed using the developed RP-HPLC method. The chromatographic evaluation revealed no additional peaks at the retention times corresponding to known Empagliflozin impurities, and no unidentified degradation products were observed under any of the stress conditions tested.

These findings demonstrate that the drug substance, in combination with excipients, remains chemically stable and does not undergo significant degradation under the tested conditions. This confirms the specificity of the developed method for Empagliflozin and its impurities, as it was able to separate and detect potential degradation products with high precision.

The summary of the forced degradation results is presented in Table 2, while representative chromatograms for each condition are provided in Figure 3 for visual confirmation.

Table 2. Forced degradation study results

| Parameter | Conditions | Peak area | ||

| Empagliflozin Impurity D | Empagliflozin Sugar Dimer Impurity | Any Unknown impurity | ||

| Acid degradation | 3 mL 0.1 N HCl at 60°C for 6 hours | 36276 | 9961 | Not detected |

| Alkali degradation | 3 mL 0.1 N NaOH at 60°C for 6 hours | 36339 | 10004 | Not detected |

| Oxidative degradation | 1 mL of 3 % v/v H2O2 at room temperature for 15 minutes | 36245 | 9959 | Not detected |

| Photolytic degradation | Sunlight for 24 hours | 36290 | 9986 | Not detected |

| Thermal degradation | Hot air oven at 1100 C for 24 hours | 36358 | 9972 | Not detected |

Fig. 3. Chromatogram of acid stressed sample (a); alkali stressed sample (b); oxidative stressed sample (c); photolytic stressed sample (d) and thermal stressed sample (e)

Linearity. Linearity was demonstrated at six different concentration levels prepared from standard stock solutions and impurity stock solution. It was performed from 0.0375 – 0.2250 ppm for both impurities i.e., Empagliflozin Impurity D and Empagliflozin Sugar Dimer Impurity. The graph was plotted for impurity concentration versus peak area and determined the coefficient of determination. A linear response was obtained over studied concentration range. The results were reported in Table 3andlinearity plots are shown in Fig. 4.

Table 3. Linearity results

| Linearity Level | Concentration (ppm) | Peak area | ||

| Empagliflozin Impurity D | Empagliflozin Sugar Dimer Impurity | Empagliflozin Impurity D | Empagliflozin Sugar Dimer Impurity | |

| 1 | 1.0375 | 1.0375 | 7728 | 3147 |

| 2 | 1.0750 | 1.0750 | 23633 | 5356 |

| 3 | 1.1125 | 1.1125 | 30536 | 7542 |

| 4 | 1.1500 | 1.1500 | 37367 | 9731 |

| 5 | 1.1875 | 1.1875 | 43949 | 21014 |

| 6 | 1.2250 | 1.2250 | 51280 | 23060 |

| Coefficient of determination (R2) | 0.999 | 0.999 | ||

Fig. 4. Linearity plot of Empagliflozin Impurity D (a) and Empagliflozin Sugar Dimer Impurity (b)

Precision. The repeatability (precision) and intermediate precision were performed. The repeatability was evaluated by analyzing the six replicates of impurity spiked sample solutions with respect to targeted impurity standard concentration. The intermediate precision was evaluated by analyzing the six replicates of impurity spiked sample solutions with respect to targeted impurity standard concentration on different day. The results were reported in Table 4.

Table 4: Precision results

| Injection | Repeatability (Peak area) | Intermediate Precision (Peak area) | ||

| Empagliflozin Impurity D | Empagliflozin Sugar Dimer Impurity | Empagliflozin Impurity D | Empagliflozin Sugar Dimer Impurity | |

| 1 | 26987 | 8796 | 27869 | 8753 |

| 2 | 26763 | 8956 | 28786 | 8673 |

| 3 | 27873 | 8625 | 27673 | 8524 |

| 4 | 27561 | 8737 | 26763 | 8579 |

| 5 | 28038 | 8498 | 26874 | 8653 |

| 6 | 26451 | 8835 | 27684 | 8972 |

| Average | 27279 | 8741 | 27608 | 8692 |

| Standard Deviation | 639.6 | 161.6 | 737.4 | 158.1 |

| % RSD | 2.3 | 1.8 | 2.7 | 1.8 |

Accuracy. Accuracy was determined by calculating the mean percentage recovery of Empagliflozin impurity D and Empagliflozin Sugar Dimer impurity by standard addition method. It was studied atthree different levels, 50%, 100% and 150% of Empagliflozin impurity D and Empagliflozin Sugar Dimer impurity working concentration. At each level prepared samples in triplicate and injected into chromatographic system. The results were reported in Table 5.

Table 5. Accuracy results

| Accuracy level (%)* | Concentration (µg/mL) | Amount Found (mg) | % Recovery | Mean % Recovery (% RSD) | ||||

| Empagliflozin Impurity D | Empagliflozin Sugar Dimer Impurity | Empagliflozin Impurity D | Empagliflozin Sugar Dimer Impurity | Empagliflozin Impurity D | Empagliflozin Sugar Dimer Impurity | Empagliflozin Impurity D | Empagliflozin Sugar Dimer Impurity | |

| 50 % | 0.0750 | 0.0750 | 0.7495 | 0.7724 | 99.93 | 102.98 | 102.57 (2.77) | 100.77 (2.26) |

| 0.7666 | 0.7568 | 102.21 | 100.91 | |||||

| 0.7918 | 0.7382 | 105.57 | 98.43 | |||||

| 100 % | 0.1500 | 0.1500 | 1.5027 | 1.4975 | 100.18 | 99.83 | 98.27 (3.90) | 103.62 (3.37) |

| 1.5116 | 1.5647 | 100.77 | 104.31 | |||||

| 1.4079 | 1.6007 | 93.86 | 106.71 | |||||

| 150 % | 0.2250 | 0.2250 | 2.2536 | 2.2345 | 100.16 | 99.31 | 98.53 (1.90) | 103.52 (3.88) |

| 2.1710 | 2.3387 | 96.49 | 103.94 | |||||

| 2.2259 | 2.4145 | 98.93 | 107.31 | |||||

*With respect to targeted impurity standard concentration

LOD and LOQ. The sensitivity of the proposed method of Empagliflozin impurity D and Empagliflozin Sugar Dimer impurity for measurement was estimated in terms of Limit of Detection (LOD) and Limit of Quantification (LOQ). The LOD and LOQ were calculated by using the slope of calibration curve method and standard deviation of response and intercept. The results were reported in Table 6 and chromatograms are shown in Fig. 5.

Table 6. LOD and LOQ results

| Parameter | Limit of detection | Limit of quantitation | ||

| Empagliflozin Impurity D | Empagliflozin Sugar Dimer Impurity | Empagliflozin Impurity D | Empagliflozin Sugar Dimer Impurity | |

| Standard deviation | 899.4 | 183 | 899.4 | 183 |

| Slope | 183268 | 58459 | 183268 | 58459 |

| Concentration (µg/mL) | 0.016 | 0.010 | 0.049 | 0.031 |

Fig. 5. Chromatogram of limit of detection (a) and limit of quantitative (b)

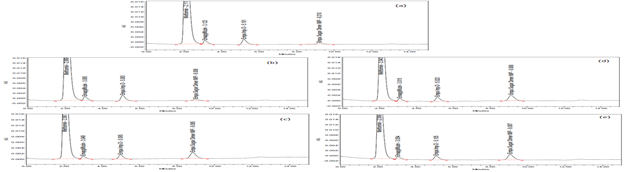

Robustness. In Robustness study, deliberate change in the flow rate, mobile phase composition was made to evaluate the impact of changed parameters on the method. The blank and standard solution was injected for each robustness parameter. The flow rate was varied from 0.8 ml/ minute to 1.2 mL/minute. From the results, it was observed that the variation in flow rate did not affect the method significantly. Hence, it can be concluded that the method is robust even by change in the flow rate ± 20%. The organic composition in the mobile phase (Buffer pH 3: Methanol, v/v) varied from 300: 630 v/v and 300: 770 v/v. From the results, it was observed that the variation in flow rate did not affect the method significantly. Hence, it can be concluded that the method is robust even by change in the organic composition in the mobile phase ± 10 %. The results were reported in Table 7 and chromatograms are shown in Fig. 6.

Table 7. Robustness results

| Parameters | Changed value | Empagliflozin Impurity D | Empagliflozin Sugar Dimer Impurity | USP Resolution * | ||||

| Retention time (minutes) | USP Plate Count | USP Tailing | Retention time (minutes) | USP Plate Count | USP Tailing | |||

| Flow rate (mL/min.) | 0.8 | 5.514 | 3737 | 1.50 | 9.498 | 3140 | 0.91 | 7.7 |

| 1.0 | 5.054 | 3687 | 1.42 | 9.073 | 3577 | 1.28 | 7.45 | |

| 1.2 | 4.728 | 4738 | 1.56 | 8.627 | 3236 | 1.29 | 6.8 | |

| Change in organic composition in the mobile phase (Buffer pH 3: Methanol, v/v) | 300: 630; v/v | 5.483 | 3612 | 1.49 | 9.287 | 3341 | 1.29 | 7.9 |

| 300: 700; v/v | 5.054 | 3687 | 1.42 | 9.073 | 3577 | 1.28 | 7.45 | |

| 300: 770; v/v | 4.926 | 4866 | 1.50 | 8.714 | 3962 | 0.91 | 6.3 | |

* Between Empagliflozin Impurity D and Empagliflozin Sugar Dimer Impurity

Fig. 6. Chromatogram of robustness study: As per method flow rate (1 mL/min) and organic composition in the mobile phase (Buffer pH 3: Methanol, 300: 700, v/v) (a); Robustness for decreased flow rate (0.8 mL/min) (b), Robustness for increased flow rate (1.2 mL/min) (c), Robustness for decreased organic composition in the mobile phase (Buffer pH 3: Methanol, 300: 630, v/v) (d) and Robustness for increased organic composition in the mobile phase (Buffer pH 3: Methanol, 300: 770, v/v) (e).

CONCLUSION

A novel, simple, precise, and robust RP-HPLC method was successfully developed for the estimation of impurities present in Empagliflozin within a combined pharmaceutical dosage form. The primary objective of this method was to ensure accurate detection and quantification of both known and potential impurities that may arise during formulation or storage.

The method was extensively validated according to regulatory guidelines, demonstrating excellent linearity, accuracy, precision, specificity, and robustness across the tested concentration ranges. These results confirm the reliability and reproducibility of the procedure under varied analytical conditions.

Due to its high sensitivity and reproducibility, the developed RP-HPLC method is well-suited for the routine quantification of Empagliflozin impurities in combined dosage forms. Moreover, its robustness makes it a practical choice for quality control laboratories, where routine testing is required to ensure the safety, efficacy, and consistency of pharmaceutical products.

By providing an efficient analytical approach, this method contributes significantly to the pharmaceutical industry’s efforts in maintaining stringent standards of drug quality and regulatory compliance.

REFERENCES

- Manoel, J.W.; Primieri, G.B.; Bueno, L.M.; Ribeiro, N.; Volpato, N.M.; Garcia, C.V.; Scherman Schapoval, E.E.; Steppe, M. The Application of Quality by Design in the Development of the Liquid Chromatography Method to Determine Empagliflozin in the Presence of its Organic Impurities, RSC Advances, 2020, 10, 7313–7320. RSC Publishing

- Jaiswal, S.H.; Katariya, M.V.; Katariya, V.R.; Karva, G.S.; Koshe, K. Validated Stability-Indicating HPLC Method for Determination of Process-Related Impurities in Empagliflozin Drug Substances, World Journal of Pharmaceutical Research, 2017, Vol. 6, Issue 7, pp. 1025–1037. wjpr.s3.ap-south-1.amazonaws.com

- Bhawani, S.; Ganesh Kumar, T.N.V. Separation of Empagliflozin and Its Impurities by Validated Stability Indicating HPLC Method and LC-MS Characterization of Oxidative Degradation Product, Asian Journal of Chemistry, 2023, Vol. 35(6), 1401-1407. asianpubs.org

- Mohan, K.G.V.; Venkatesh, K. Assessment of Organic Impurities in Solid Oral Product of SGLT-2 Inhibitors Category (Empagliflozin) by HPLC, J RNA Genom, 2022, S03(006), 1-6. Allied Academies

- Patil, A.S.; Amrutkar, S.V.; Nalwade, S.; Patil, A.B. A Validated Stability Indicating High Performance Liquid Chromatographic Method for Determination of Impurities in Empagliflozin Film Coated Tablets, Research Journal of Pharmacy and Technology, 2025, 18(2), 639-646.

- Validation of Analytical Procedure: Text and Methodology,Q2(R1). ICH guidelines, 2005.