Introduction

Dental ceramics have developed increasingly and become popular because of their inimitable properties such as biocompatibility, chemical stability and superior aesthetic qualities. However, one of the inherent disadvantages of dental ceramic restorations is their brittle nature. This brittle behaviour combined with the presence of surface and internal flaws may result in a low strength and consequently has limited the clinical use of ceramics such as those based a leucite reinforcement (Wiederhorn, 1969).

The leucite reinforced ceramics often be unsuccessful at stresses below their reported strength values as results of either internal or processing weaknesses. The former could be due to residual stresses, large grains and micro cracks resulting from the differences in the thermal expansion between the glassy matrix and the crystalline phases of the leucite (Shareef et al., 1994), whereas the latter could be machining scratches, impurity phases and porosity (Kingery et al., 1976). The strength for a certain material will, consequently, depend on the number and size of weaknesses that are incorporated within the material. These deficiencies in the materials are expected to be connected with sharp cracks which are not exposed by investigation of the fracture surface, since they form an indistinguishable part of the fracture surface (Shareef et al., 1991).

Resent studies have shown that grinding process caused a significant reduction in the flexural strength of the feldspathic porcelains, whereas polishing and glazing have a significant increase of the flexural strength of the same porcelains (Williamson et al., 1996 and Giordano et al., 1995). Southan (1987) found that scratches of a depth 30-40 mm in feldspathic porcelain specimens caused a reduction of about 75% in the biaxial flexural strength (BFS).

Hussain et al. (1979) and Baez and Blackman (1988) inspected the effect of chemical etching on the strength of some dental ceramics using either hydrofluoric acid (HF) or ammonium fluoride (NH4F). They found a decrease in strength of 20 to 30% for aluminous porcelain and a cast-able glass ceramic. Jones (1983) showed a reduction of 40% in strength of one brand of feldspatic dental porcelain rods and no weakening influenced of another brand after etching with HF. Levy (1987) found no significant difference in the flexural strength values of some dental ceramics when the surface was chemically etched. These suggest that the strength of dental porcelains is not always dependent on the features of the surface.

There is thus inconsistent information in the impact of surface treatments on the strength of dental ceramics. This is because the strength depends on the relationship between the fracture toughness (Kic) and the flaw size (Kingery et al., 1976), as shown in Equation 1:

Where is fracture strength, Kic is fracture toughness, C is flaw size and Y is the geometric constant. The Kic values were obtained from results reported by Bieniek and Marx (1994).

Therefore, it is vital to evaluate the impact of surface treatments on the strength of dental ceramics.

The objective of this study was to evaluate the impact of three surface preparations namely polishing, grit blasting and etching on the biaxial flexural strength (BFS) of the fit surface of four dental ceramics and establish whether surface or internal flaws control the BFS.

Materials and Methods

Four commercial available dental ceramics were used in this investigation, namely Chameleon (CH), Mirage (MI), Optec-HSP (OP) and Flexoceram (FL) as detailed in Table 1.

Table 1: Details of dental ceramics used in this investigation.

| Materials’ Name | Designated Code | Shade No. | Batch No. | Supplier |

| Chameleon | CH | Body D-4 | 059020 | Myron Int. Inc. Kansas, USA |

| Mirage | MI | Body D-4 | 8130 | Myron Int. Inc. Kansas, USA |

| Optec-HSP | OP | A2 | B1637E | Jeneric, Conn., USA |

| Flexoceram | FL | D-EB1 | 442 | Elephant Ceramics, Hoorn, Netherlands |

Four groups of ten specimens were fabricated for each material. A mixture of ceramic powder and condenser liquid (Myron, Inc., Kansas, USA) was cast into a silicon rubber mould 12mm in diameter ´ 3mm thick and vibrated to condense the particle and then fired according to the suppliers’ procedures applicable to each ceramic. The fired discs were ground with 600 grit SiC paper (Buehler-Met, Metallographic Grinding Paper, UK), to produce flat parallel surfaces and their thickness was measured by a micrometer screw gauge (Mitutoyo, Japan). Ten specimens of each material were exposed to three surface treatments, namely: polished with diamond paste down to 1 µm, grit blasted (alumina 50 µm) and etched with 10% HF for periods of 30 s and 2 min. Some samples were gold coated for examination under BSI and SEM (Shareef, et al. 1994).

The biaxial flexural strength (BFS) values for ten discs of each material were evaluated by employing each specimen on an annular knife edge 9mm in diameter and loaded with a 3mm ball-ended indentor in a Lloyd M5K universal testing machine at a cross-head speed of 0.5 mm per min. The samples were loaded to failure and the maximum BFS values were calculated using the equation reported by other investigator (Piddock et al., 1984). Assuming a Poisson’s ratio (n) of porcelain of 0.25, the simple form of this equation is:

Where sf is the biaxial flexural strength (BFS), P is the load to rupture, a is the radius of the knife-edge support and h is the sample thickness.

Statistical assessments between groups were prepared using one-way analysis variance (ANOVA) significant difference test.

Results

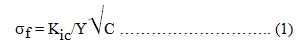

BFS data for each group of CH, MI, OP, and FL are sketched in Figure 1 and detailed in Table 2. Statistical analyses of these results are shown in Table 2 with analysis of variance (ANOVA) and Tukey HSD tests used to evaluate significance between groups. The results show no significant difference in the BFS for the polished and grit blasted. In contrast, the BFS reduced after etching with 10% HF (2 min), which was significant for CH (42 MPa), OP (64 MPa) and FL (42 MPa) (one-way ANOVA, P<0.05), but not for MI (64 MPa).

Table 2: The mean values of flexural strength and standard deviation as a function of surface treatments of dental ceramics used in this investigation.

| Materials’ Code | Biaxial Flexural Strength/ MPa(±SD)* | |||

| Surface Treatments** | ||||

| PS | GBS | LES | HES | |

| CH | 63.6(±8.7) | 60.5(±7.2) | 64.8(±3.7) | 41.7(±5.7) |

| MI | 78.0(±15.5) | 77.7(±16.9) | 73.8(±16.2) | 63.7(±19.2) |

| OP | 102.8(±17.5) | 101.1(±12.8) | 89.1(±14.8) | 63.1(±17.8) |

| FL | 60.9(±6.8) | 61.7(±5.7) | 59.3(±8.4) | 42.3(±15.4) |

*SD = Standard Deviation

** Surface Treatments: Polished Surface (PS), Grit Blasted Surface (GBS), Light Etched Surface (LES-30 s), Heavy Etched Surface (HES-2min)

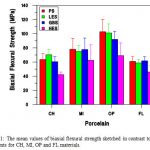

Values for the average flaw size (C) were calculated using Equation (1) and are shown in Figure 2 and detailed in Table 3. The fracture toughness (Kic) values were acquired from data reported by Bieniek and Marx (1994) and the BFS data of this investigation were used for sf.

The microstructural features were examined using Back Scattering Imaging (BSI) and Scanning Electron Microscope (SEM). The BSI images are shown in Figure 3a-d for CH, MI, OP and FL respectively. Also, Figure 4a-c shows example of SEM micrographs of CH, MI and FL respectively.

|

Discussion

As shown in Fig. 1, the BFS decreased significantly for samples prepared from CH, OP and FL materials when etched with 10% HF for a period of 2 min, whereas polishing and grit blasting treatments have no impact on the BFS.

The reduction in the BFS values after etching with 10% HF is most likely due to an increase surface flaw size which would be sufficient to induce fracture initiation from the surfaces. Other investigators have also found that a decrease in the range of 20% to 40% in the strength values after acid etching of dental ceramics (Hussain et al., 1979; and Jones 1983). However, it should be noted that etching with HF does not always has impact on the BFS values.

Levy (1987) reported that no significant difference in the flexural strength values of some dental ceramics between polishing with pumice and etching after air and vacuum glazing and over glazing. Also, Jones (1983) reported that a reduction of 40% in strength of one brand of feldspatic dental porcelain rods and no weakening effect of another brand when etched with HF.

The BFS was unaffected for the samples polished with diamond paste down to 1 µm and grit blasted (alumina 50 µm). This suggests that the BFS is ruled primarily by the internal flaw size. However, Sano et al. (1989) reported that feldspathic porcelain samples showed a higher four-point flexural strength when polished with 0.3 µm alumina. Sherrill and O’Brien (1974) found that no difference between the strength of feldspathic porcelain samples when their surfaces were fine polished or auto-glazed. Fairhurst et al. (1992) and Giordona et al. (1994), on the other hand showed that polishing surfaces with 1 µm and 15 µm diamond pastes produced significant stronger specimens than auto-glazing. Also, it has been reported that no statistically significant differences in the load at failure of glazed porcelain and polished auto-glazed porcelain (Brackett et al. 1989). However, polishing the glazed specimens showed higher strength values (Levy 1987).

Table 3: The mean values of flaw size as function of surface treatment for MI, OP and FL materials.

| Materials’ Code | Surface Treatment | Calculated Flaw Size

(±SD) (mm)* |

| MI

|

PS

GBS ES |

102.9 (47.3)

102.8 (41.1) 190.5 (111.5) |

| OP

|

PS

GBS ES |

134.4 (65.4)

156.9 (40.4) 314.0 (148.2) |

| FL

|

PS

GBS ES |

115.2 (23.2)

111.0 (18.8) 216.1 (79.8) |

* K1c values was taken from Bieniek and Marx (1994).

These suggested that the characteristic properties of dental porcelains are not always dependent on the characteristics of the surface.

A measure of the severity of fracture-initiating flaws can be acquired from the measured values of strength and fracture toughness by assuming that the flaws had a particular simple geometry (Equation 1). Therefore, usable strength is a function of flaw size.

Based on the present data the calculated flaw size was around 100 mm (Figs. 2, 3 &4), which corresponds well to the observed internal cracks size that have been reported in the earlier investigation by Shareef et al., 1994.

|

Figure 2: The mean values of flaw size sketched in contrast to surface treatments for MI, OP, and FL materials. |

|

|

Figure 4: SEM micrographs of the appearance of clusters of leucite crystals exposed by light etching with 1% HF for 30 s (Shareef et al. 1994) for: |

Conclusions

- The BFS for the polished and grit blasted surface finishes of dental porcelain used in this investigation is control primarily by the internal flaw size.

- Etched surfaces (10% HF for 2min) caused a reduction in the BFS values because the large surface flaws created control the fracture process.

- The calculated flaw size values were confirmed by the BSI and SEM micrographs.

References

- Bieniek KW, Marx R. Die mechanische belastbarkeit neuer vollkeramischer kronen-und bruckenmaterialien. Schweiz Monatsschr Zahnmmed 104: 284-289, 1994.

- Baez R, Blackman R. Glazing inside surface of castable ceramic crown segments to improve strength. J Dent Res, Abstr. No. 378, 1988.

- Brackett S, Leary J, Turner K. An evaluation of porcelain strength and the effect of surface treatment. J Prosthet Dent 61: 446-451, 1989.

- Fairhurst CW, Lockwood PE, Ringle RD, Thompson WO. The effect of glaze on porcelain strength. Dent Mater 8: 203-207, 1992.

- Giordano R, Cima M, Pober R. Effect of surface finish on the flexural strength of feldspathic and aluminous dental ceramics. Int J Prosthodont 8: 311-319, 1995.

- Giordano RA, Campbell S, Pober R. Flexural strength of feldspathic porcelain treated with ion exchange, overglaze and polishing. J Prosthet Dent 71: 468-472, 1994.

- Hussain MA, Bradford EW Charlton G. Effect of etching on the strength of aluminous porcelain jacket crowns. Br Dent J 147: 89-90, 1979.

- Jones DW. The strength and strengthening mechanisms of dental ceramics. In: McLean, JW (ed). Dental Ceramics. Proceeding of the First International Symposium on Ceramics. Chicago: Quintessence Pub, 83-136, 1983.

- Kingery WD, Bowen HK, Uhlmann DR. Introduction to ceramics. 2nd ed. New York: John Wiley & Sons, 768-814, 1976.

- Levy H. Effects of laboratory finishing techniques on the mechanical properties of dental ceramics. Int Dent J 69: 1039-1045, 1987.

- Piddock V, Marquis PM, Wilson HJ. The role of platinum matrix in porcelain jacket crowns. Br Dent J 157: 275-280, 1984.

- Sano Y, Fujisawa M, Shinohara K, Uetani T, Tadona H, Horoguchi H, et al. The influence of surface properties on the bending strength of Optec porcelain. J Gifu Dent Soc 16; 577-581, 1989.

- Shareef MY, van Noort R, Messer PF, Piddock V. The effect of microstructural features on the biaxial flexural strength of leucite reinforced glass-ceramics. J Mater Sci: Materials in Medicine 5: 113-118, 1994.

- Shareef, MY, Messer, PF and van Noort, R. The Fracture Behaviour of Machineable Hydroxyapatite. Ceram. Soc., Ceramics Transaction, New York, 17: 79-118.glass-ceramics. J Mater Sci: Materials in Medicine 5: 113-118, 1991.

- Sherrill CA, O’Brien WJ. Transverse strength of aluminous and feldspathic porcelain. J Dent Res 53: 683-690 ,1974.

- Southan DE. Effect of surface injury on chemically strengthened dental porcelain. Quintessence Int 18; 575-580, 1987.

- Wiederhorn SM. Fracture of Ceramics. In: Wachtman JB (ed). Mechanical and thermal properties of ceramics. Washington, DC: NBS Special Publication 303: 217-241, 1969.

- Williamson RT, Kovarik RE, Mitchell RJ. Effect of grinding, polishing and overglazing on the flexural strength of a high-leucite feldspathic porcelain. Int J Prosthodont 9: 30-37, 1996.