Introduction

Plastics waste management remains a major environmental issue due to over population and rapid economic development. The complete degradation of plastics mainly polyethylene remains a challenge and the current work is focused on enhancing the biodegradation of polyethylene. The photo degradation followed by biodegradation of PE could be enhanced by the use of bio-based additives [1-26].

Experiment

Material and methods

General purpose film grade LDPE has been used to prepare films. Banyan dry leaves powder were used

Blending and film preparation of LDPE

The Banyan dry leaves powder was melt blended with LDPE at three different formulations 1, 3 & 5% respectively in (Haake, Rheomex OS, PTW16, Thermo scientific, Germany) Modular Torque Rheometer. The Modular Torque Rheometer blending was carried out at temperature range of 100-190 °C (from die to hopper) & a screw speed of 100 rpm. Subsequently, the pellets are dried in a dehumidifier at 70°C for two hours to remove moisture. The pellets produced were subsequently dried & subjected to film cast process to produce films of 50 µ thicknesses.

Photodegradation

All blended samples were subjected to photodegradation studies using QUV UV Weather-o-meter.

Titration method of CO2 determined test (ASTM D 5338)

The details of the biodegradation experiment are summarized below;

Sample detail

Before and after brittle fragmented photodegraded LDPE -Banyan dry leave powder

Conditions of reaction mixtures

Origin of compost : Municipal and vegetable waste

Reaction Temperature : 58o C

Dry Solid (%) : 52%

Volatile Solid (%) : 20

Air flow rate : 100 ml/min

Test duration (day) : 90 days

PH : 7.4

Reference material : Cellulose

Volume of reaction vessel : 3000 ml

The preparation and ageing of the compost for biodegradation of film samples was carried out as per the standard. The PH value for all the samples, control and blank was maintained. Barium Hydroxide solution (0.024 N) was prepared by dissolving 4.0 g of anhydrous barium hydroxide in 1000ml of distilled water. The solution was filtered and the normality was determined by titrating against standard acid solution and stored in a sealed container as a clear solution to prevent absorption of CO2 from air. About 5-20 L of 0.024 N barium hydroxide solutions was prepared at a time for running a series of tests. However, care was taken that a film of BaCO3 does not form on the surface of the solution in the glass vessels, which would inhibit CO2 diffusion into the absorbing medium.

Procedure

The composting vessels were incubated in diffuse light minimum for a period of 90 days & the temperature of the system was maintained at 58±2 °C. The CO2 & O2 concentrations were checked in the outgoing air daily with a minimum time interval of 6 hrs after the first week. The air flow was adjusted to maintain a CO2 concentration of at least 2% volume to allow accurate determination of CO2 level in the exhaust air. Composting vessels were shaken weekly to prevent extensive channeling which could provide uniform attack of microbes on test specimen and provide an even distribution of moisture. The incubation time was fixed for 90 days.

|

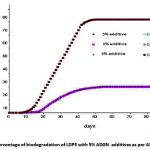

Figure 1: The percentage of biodegradation of LDPE with 5% ADGN additives as per ASTM D 5338

|

Carbon dioxide analysis

The carbon dioxide (CO2) produced in each vessel reacted with Ba(OH)2 and was precipitated as barium carbonate (BaCO3). The amount of carbon dioxide produced was determined by titrating the remaining barium hydroxide with 0.05 N hydrochloric acid to a phenolphthalein end point. Because of the static incubation, the barium carbonate built up on the surface of the liquid was broken up periodically by shaking the vessel gently to

ensure continued absorption of the evolved carbon dioxide. The hydroxide traps were removed and titrated before their capacity exceed. At the time of removal of the traps, the vessel was weighed to monitor moisture loss from the soil and allowed to sit open so that the air was refreshed before replacing fresh barium hydroxide and releasing the vessel. The carbon dioxide evolution rate reaches a plateau when all of the accessible carbon is oxidized. The test was terminated at this point. At the conclusion of the test, the pH and moisture and ash content of the soil is measured and recorded.

Result and Discussion

Biodegradation of the LDPE with Banyan dry leave powder

As shown in Figure 1 conditions of reaction mixtures: Organ of compost; livestock excrement, municipal and Vegetable waste used the method used for the determination of the biodegradability of the LDPE was based on the International Standard (ASTM D 5338-98) that measures the evolved CO2 amount from both the blank vessel without a sample and the sample vessel including a 10 g LDPE –Banyan dry leaves powder samples. According to ASTM D 5338 test procedure. Fragments occur progressively in the biodegradation of the photodegradaded films. Moreover, the biodegradation test results reveals that the LDPE-Banyan dry leaves powder additives shows 30% of biodegradation on photo degraded LDPE films when observed at the end of 90 days.

Conclusion

LDPE- Banyan dry leave powder shows improvement in photodegradation rates. After the photo degradation subjected to biodegradation, the percentage of biodegradation was 30% at the end of 90 days as per ASTM D 5338.

Reference

- C. Abrusci. Biodegradation of phot-degraded mulching films based on polyethylene’s and stearated of cacium and iron as pro-oxidant additives. International biodeterioration & biodegradation. 65,451-459. 2011.

- Bevington, JC et.al. Further study of fluorinated derivatives of benzoyl peroxide as initiators of radical polymerizations: kinetic chain lengths and related quantities. J.Eur Polym. 34,539. 1998.

- Bheki Magagula et.al. Mn2 Al-LDH- and Co2Al-LDH- stearate as photodegradants for LDPE film. Poly.deg. stab. 94, 947-954. 2009.

- Dauria, M., Rocco Racioppi. Photochemical dimerization of esters of urocanic acid. Journal of Photochemistry and Photobiology A Chemistry. 112,145-148. 1998.

- Ekhlas Eltayeb et.al. The effect of Cobalt Napthenate and 2-hydroxy 4- methoxybenzophenone and photo-oxidative degradation of LDPE. Iranian Polymer Journal. 18(9), 753-760. 2009.

- Fontanella S et al. Comparison of the biodegradability of various polyethylene films containing pro-oxidant additives, doi: 10.1016/j.polymdegradstab.2010.03.009. 2010.

- Flavia G.D et.al. Evaluation of photodegradation in LDPE/modified starch blends. Polymeros: Ciencia Technologia. 19(4),313-317. 2009.

- MH. Grant. Editor. Encylopedia of chemical technology, New York: Wiley, 8. 1991.

- Gerhard Knothe National Center for Agricultural Utilization Research, Agricultural Research Service, U.S. Department of Agriculture, Peoria, IL, USA. 2006

- Gulmine, JV., et.al. Degradation profile of polyethylene after artificial accelerated weathering. Polymder Degradation Stability. 79, 385-97. 2003.

- International standard ASTM D 5338-98. Compost biodegradation Evaluation of the ultimate aerobic Biodegradability of plastic material in method by analysis of released carbon dioxide an aqueous medium. 2003.

- Jakubowicz, I. Evaluation of degradability of biodegradable polyethylene. Polymer Degradation and Stability. 80,39-43. 2003.

- Khabbaz, F., Albersson, AC., Karlson, S. Chemical and morphological changes of environmentally degradable polyethylene films exposed to thermo oxidation.Polymer Degradation Stability. 63,127-38. 1999.

- Lie Ken Jie, M.S.F. and Cheng, A.K.L. Confirmation of the carbon chemical shifts of ethylenic carbon atoms in methyl ricinoleate and methyl ricinelaidate. Natural Prod. Lett. 3, 65-69. 1993.

- Marcelo A.G. Bardi. Effect of ionizing radiation on mechanical and thermal properties of low- density polyethylene containing pro-degradant agents. international Nuclear atomic conference-INAC. 2009.

- Marek Koutny et.al. Biodegradation of polyethylene films with prooxidante additives. 64,1243-1252. 2006.

- Nils B. Vogt. et.al. Oxo-biodegradable polyolefins show continued and increased thermal oxidative degradation after exposure to light, Poly.deg.stab.94, 659-663. 2009.

- Qun yan et.al. Bio synthesis and thermal properties of Poly( 3- hydroxybutyrate-co-3 hydroxyl valerate) with large variety of hydroxyvalerate content by bacillus cereus, Chinese journal of polymer science. 25(4),341-345. 2007.

- Qureshi, FS et.al. Weather induced degradation of linear low density polyethylene: mechanical properties. J polym. Eng. 9, 67-84. 1990.

- Rouhollah , Bagheri. Study of the effect of r- absorbed dost on degradation of Polypropylene/ starch- filled polymer conating photo-initiotors by spectroscopic methods. Radiation Physics and chemistry. 78,765-769. 2009.

- P.K.Roy et.al. Studies on the photo-oxidative degradation of LDPE films in the presence of oxidised polyethylene, Poly. degrad. Stab. 92, 1151-1160. 2007.

- Telm Ojeda et.al. Degradability of linear polyolefins under natural weathering. Poly. deg.stab. 96;703-707. 2011.

- Telm Ojeda et.al. Abiotic and biotic degradation of oxo-biodegradable foamed polystyerene. Poly. deg. stab. 94,2128-2133. 2009.

- Thangavelu Muthukumar et.al Effect of environment on the degradation of starch and pro-oxidant blended polyolefins. 95,1988-1993. 2010.

- Yamashita, T et. al. Benzophenone-photosensitized alkylation of arylalkenes with acetone, dimethyl sulfoxide, and their related compounds in the presence of tert-butylamine. 118;165-171. 1998.

- A.U.Santhoskumar, K. Palanivelu, A new additive formulation to enhance photo and biodegradation charactersticis of polypropylene, International journal of polymeric material and bio polymeric material. 61(10),793-808. 2012.